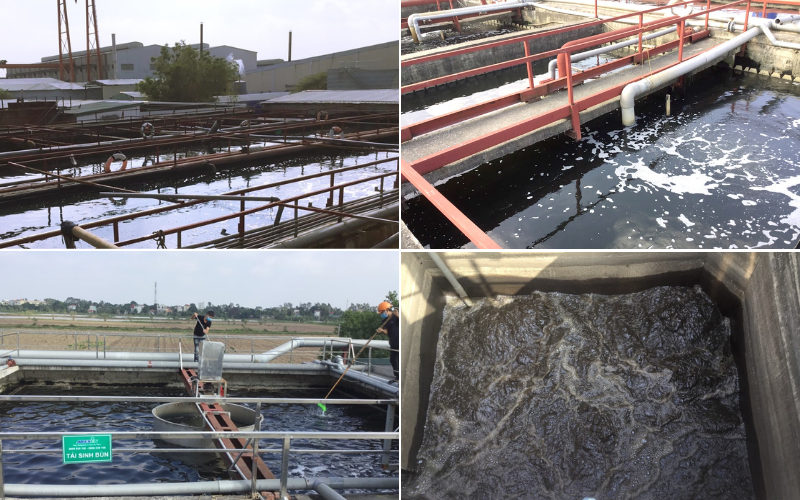

Aerotank (also known as aerobic activated sludge tank) in textile dyeing wastewater treatment system, is an aerobic biological wastewater treatment method, in which oxygen is supplied and the wastewater is mixed with activated sludge continuously to take place the decomposition reactions of organic substances, organic compounds.

Foaming in the aerobic tank is one of the problems in many wastewater treatment systems. Foam is usually sticky, viscous, and colored. Foam often floats, rises and accumulates on storage tanks, thereby reducing wastewater quality and making it difficult to control sludge retention time.

Foam can also spill onto walkways and surrounding areas, posing serious operational difficulties and risks to operations, operators and the environment. Let’s ARES Environment learn the causes and solutions to overcome the problem of foaming in the Aerotank tank in the textile dyeing wastewater treatment system:

1/ Phenomena:

The pH in the “Aerotank” and behind the “Aerotank” began to decrease, the decrease lasted for 2-3 days before it became apparent, sometimes it decreased to 4.5-5;

The water after settling has residue drifting out, microorganisms begin to die;

The floating foam in the sedimentation tank is usually large, easy to break when it meets water, but it will be smooth and difficult to break when watered a lot to break the large foam.

2/ Causes:

Wastewater input change mutant or change in concentration generate pollution in wastewater causes sudden pH change, microorganisms are shocked load;

Aerotank is contaminated with foreign substances outside the receiving source, weakening microorganisms, damaged activated sludge;

Microorganisms in the Aerotank are old or dead due to the incorrect dosage and cycle of adding microorganisms and make the activated sludge broken;

3/ Troubleshooting Procedure:

The solution to the problem of foaming depends on the cause that the operator offers:

- Step 1: Clear broken activated sludge in Aerotank;

- Step 2: Add new activated sludge in Aerotank;

- Step 3: Activate microorganisms in the Aerotank;

- Step 4: Take a part of the cultured sludge in the Aerotank and store it in the Sludge regeneration tank to provide sludge circulation for the Aerotank;

- Step 5: Periodically add enough microorganisms to the Aerotank;

In this article, ARES Environment only gives 3 common causes that is often encountered in the process of taking care of and maintaining and supporting customers to troubleshoot operating problems of wastewater treatment systems.

In addition, there are many other causes such as growth of filamentous microorganisms, nutritional imbalance, incorrect operation of technology, error in technology after the process is put into operation, etc., leading to foaming in the textile dyeing wastewater treatment system.