Project

Wastewater treatment system for Can Dang urban area and commercial center

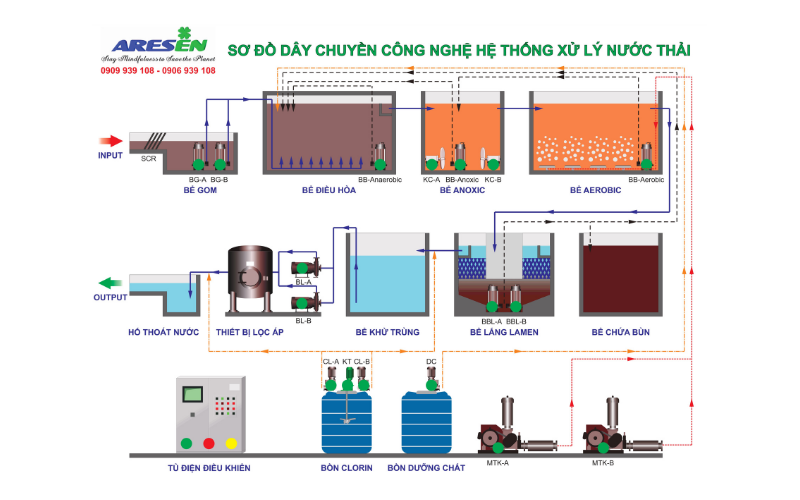

Project explanation

Organic waste decomposition tank + Grease separation tank:

Concentrated wastewater generated from the toilet is collected to the organic waste decomposition tank, where the anaerobic decomposition process will take place to reduce the concentration of pollutants and the water after the septic tank will flow back to itself. conditioning tank of the wastewater treatment system.

Because domestic wastewater often contains a high content of grease, the grease trap device is responsible for keeping the grease in the tank before it enters the treatment system, in order to reduce the possibility of clogging of the pump, pipeline & reduce the process of waste water. bioprocessor behind. Waste water from the grease separation tank is directed to the conditioning tank of the wastewater treatment system.

Anaerobic tank: The generated domestic wastewater is collected along the wastewater collection pipeline and brought to the conditioning tank. The anaerobic tank is designed with anaerobic digestion to decompose the organic solids in the wastewater from the toilet. At the same time, in this tank, a return pipe is arranged from the high-load settling tank, in order to reduce the amount of residual sludge in the biological treatment tank and dilute the pollutant concentration of the newly received wastewater stream. From here the wastewater flows itself into the sludge fermentation tank. Waste water entering the tank is distributed according to the area of the bottom of the tank. The water flows from the bottom to the top. Organic matter dissolved in wastewater is absorbed and decomposed by microorganisms. The main task of the tank is to decompose phosphorus, create an anaerobic sludge environment and activate beneficial microorganisms for the following metabolic processes.

Anoxic tank: In Anoxic tank, NO3- in wastewater generated from ammonium oxidation in aerobic tank is pumped and circulated to Anoxic tank, along with activated sludge and scraped wastewater under conditions. In the absence of oxygen, the reduction of NO3- to free N2 occurs. Total nitrogen content in wastewater is reduced to the permissible level. The process of converting organic nitrogen in wastewater in the form of ammonium to free nitrogen is carried out in two steps involving two types of autotrophic microorganisms Nitrosomonas and Nitrobacter.

Aerobic: The anoxic bioreactor combined with the aeration tank is an upgrade of the classic activated sludge system specifically designed to remove organics and nitrogenous compounds. (exists in the form of ammonium and organic nitrogen).

Oxygen (air) is supplied to the aerobic tank by air blowers and a highly efficient air distribution system with a bubble size of less than 10 m. maintained in the range of 2 – 3 mg/l to ensure adequate supply of oxygen for living organisms and to consume organic matter in the wastewater. aerobic organisms convert dissolved organic matter into water and carbon dioxide, organic nitrogen and ammonia into NO3- nitrate, (2) evenly mix wastewater and activated sludge to facilitate good contact with microorganisms. substrates to be treated, (3) release gases that inhibit the microbial life process, These gases are produced during the process of microorganism’s decomposition of pollutants, (4) positively affect the process. microbial reproduction. The organic matter load of the tank during the aerotank treatment phase ranges from 0.32 – 0.64 kgBOD/m3.day and night.

Sedimentation tank: The water after the aeration tank will be led through the settling tank. The settling tank is responsible for settling and separating the activated sludge from the wastewater. Part of the sludge will be pumped and circulated back to the anoxic tank, aeration tank to reduce N and reduce sludge biomass and enhance the ability of microorganisms to decompose organic matter. The rest will be taken to the sludge storage tank. The settling tank is designed for the purpose of settling solids in the form of suspension and suspension, eliminating odors from wastewater to improve the settling efficiency of residues in wastewater.

Disinfection tank: After removing all activated sludge suspended in the wastewater at the settling tank, it will be passed through a chlorine contact tank to remove bacteria. The water after being disinfected meets the discharge standards QCVN 14:2008/BTNMT, column A and is discharged to the receiving source.

Sludge storage tank: After a period of operation, it will definitely generate residual sludge. Excess sludge from the treatment compartments is collected in the settling tank. A part will be recirculated to the anoxic tank to provide microorganisms for biochemical process, the rest will be taken to the sludge tank. The sludge in the sludge tank after a period of operation will be full, at this time it must be sucked out and treated properly.

Project images

You need a wastewater treatment solution like this one?

Please contact us for a complete and in-depth consultation